Remove The Dus: The Ultimate Guide to Removing Dust from Your Home

By:Admin

Remove The Dus utilizes advanced filtration technology to effectively capture and eliminate pollutants such as dust, pollen, and other harmful particles. The product is designed to be easily integrated into existing HVAC systems, making it a cost-effective and efficient solution for improving indoor air quality. With its innovative design and proven effectiveness, Remove The Dus has the potential to make a significant impact on air quality and public health around the world.

In a statement, {company name} CEO expressed enthusiasm about the potential impact of Remove The Dus on global air quality. "At {company name}, we are committed to developing sustainable solutions that protect the environment and improve public health. Remove The Dus is a testament to that commitment, and we believe it has the potential to significantly reduce air pollution and create healthier living and working environments for people everywhere."

The launch of Remove The Dus comes at a critical time, as air pollution continues to be a major global health concern. According to the World Health Organization, outdoor air pollution is responsible for an estimated 4.2 million premature deaths worldwide each year. In addition, indoor air pollution is also a significant issue, particularly in urban areas where people spend the majority of their time indoors.

With its ability to effectively remove harmful particles from the air, Remove The Dus has the potential to address both outdoor and indoor air pollution, making it a versatile and impactful solution for improving air quality. Additionally, the product's integration into existing HVAC systems means that it can be easily deployed in a wide range of settings, including homes, offices, schools, and other public spaces.

In addition to its environmental and public health benefits, Remove The Dus also aligns with {company name}'s broader mission to create sustainable solutions that reduce the company's carbon footprint and promote a more sustainable future. By addressing air pollution, the product has the potential to contribute to a cleaner, healthier planet for future generations.

As {company name} prepares to launch Remove The Dus, the company is already receiving significant interest from businesses, organizations, and individuals who are eager to improve their indoor air quality and contribute to a cleaner environment. With its innovative technology and proven effectiveness, Remove The Dus is poised to make a meaningful impact on the global fight against air pollution.

The launch of Remove The Dus represents an important step forward in {company name}'s ongoing efforts to develop sustainable solutions that benefit both people and the planet. As the product becomes available to the public, it has the potential to create cleaner, safer environments for people around the world, while also supporting {company name}'s broader mission to promote sustainability and protect the environment.

With the launch of Remove The Dus, {company name} is taking a significant step forward in its commitment to environmental sustainability and public health. As the world continues to grapple with the impacts of air pollution, innovative solutions like Remove The Dus are essential for creating a cleaner, healthier future for all.

Company News & Blog

Choosing the Best Material for Conveyor Belts: A Guide

[Introduction – 100 words]The conveyor belt is an essential component for various industries to transport materials from one location to another. Recently, a new belt material has been developed by [Company Name], a leading manufacturer of conveyor belts. This innovative material is designed to improve the efficiency and durability of conveyor systems, making it a game-changer for businesses across multiple sectors. With a focus on enhancing productivity and reducing maintenance costs, the new belt material is set to revolutionize the conveyor industry.[Company Introduction – 200 words][Company Name] has been a pioneer in the conveyor belt manufacturing industry for over two decades. With a strong emphasis on research and development, the company has consistently pushed the boundaries of innovation to meet the evolving needs of its customers. Its state-of-the-art manufacturing facilities and a team of experienced engineers enable [Company Name] to deliver high-quality, customized solutions to clients worldwide.The company’s commitment to sustainability and eco-friendly practices has also set it apart in the industry. By employing advanced technology and sustainable materials, [Company Name] has maintained a strong focus on reducing environmental impact while providing top-notch products to its clients.[New Belt Material For Conveyor – 500 words]The newly developed belt material by [Company Name] promises to revolutionize the conveyor industry by addressing key challenges faced by businesses. The material is designed to withstand heavy loads, high speeds, and extreme temperatures, making it suitable for a wide range of applications. Its advanced composition provides superior resistance to wear and tear, thereby extending the operational life of conveyor systems.In addition to its durability, the new belt material offers improved grip and traction, ensuring efficient material handling and reduced slippage. This feature is particularly beneficial for industries dealing with bulk materials or goods that require precise and stable conveyance.Furthermore, the innovative material boasts a low-friction surface, reducing energy consumption and increasing overall operational efficiency. This feature aligns with [Company Name]’s commitment to sustainability and energy conservation, helping businesses lower their carbon footprint while improving their bottom line.The new belt material also incorporates advanced impact resistance, enhancing its ability to withstand harsh operating conditions. This characteristic ensures minimal downtime and maintenance, leading to significant cost savings for businesses in the long run. Additionally, its resistance to chemicals and abrasion further enhances its suitability for industries such as mining, manufacturing, and logistics.With a focus on innovation and customer satisfaction, [Company Name] has ensured that the new belt material is easy to install and maintain. Its compatibility with existing conveyor systems makes it a convenient and cost-effective upgrade for businesses looking to enhance their operations without significant disruption.The application of the new belt material extends across a wide spectrum of industries, including but not limited to food processing, automotive, pharmaceuticals, and warehousing. Its versatility and performance benefits make it an attractive choice for businesses seeking to streamline their material handling processes and improve overall productivity.In conclusion, the new belt material developed by [Company Name] represents a significant advancement in the conveyor industry. Its superior durability, enhanced grip, low-friction surface, and impact resistance set a new standard for conveyor belts, offering businesses an opportunity to optimize their operations and remain competitive in today's dynamic market. As [Company Name] continues to lead the way in innovative solutions for the materials handling industry, the new belt material is poised to make a lasting impact on businesses worldwide.

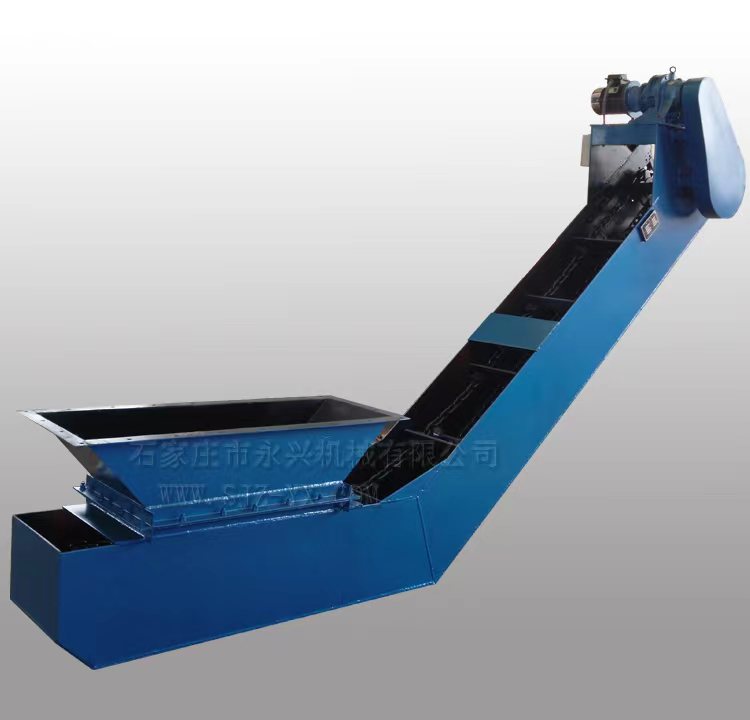

Innovative Elevated Conveyor Systems: Benefits and Uses for Your Business

Elevated Conveyor Systems: Revolutionizing Material Handling in the Manufacturing IndustryIn recent years, the manufacturing industry has seen a significant shift towards automation and advanced technologies in order to improve efficiency, productivity, and safety. One of the key developments in this space is the introduction of elevated conveyor systems, which have transformed the way materials are handled and transported within manufacturing facilities. These innovative systems have not only revolutionized the industry, but have also significantly impacted the operations and processes of companies worldwide.Brand, a leading provider of industrial automation solutions, has been at the forefront of this revolution, offering state-of-the-art elevated conveyor systems that have gained widespread recognition for their efficiency, reliability, and performance. With a strong focus on innovation and customer satisfaction, Brand has quickly become a trusted partner for many manufacturing companies looking to streamline their material handling processes.The elevated conveyor systems offered by Brand are designed to cater to a wide range of industries, including automotive, food and beverage, pharmaceutical, and more. These systems are capable of handling various types of materials, from small components to large and heavy parts, making them versatile and adaptable to different manufacturing environments. With customizable features and options, companies can tailor these systems to meet their specific requirements and operational needs.One of the key advantages of elevated conveyor systems is their ability to optimize floor space within a manufacturing facility. By lifting the conveyor system off the ground, valuable floor space is freed up for other operations, storage, or equipment. This not only improves the overall layout and efficiency of the facility, but also provides a safer and more organized working environment for employees.Furthermore, elevated conveyor systems offer enhanced flexibility and agility in material handling, allowing for seamless integration with other equipment and machinery. This level of integration contributes to a more connected and synchronized production process, ultimately leading to improved throughput and reduced cycle times. With advanced control systems and software, these systems can be easily programmed and operated to accommodate varying production requirements and schedules.Safety is a top priority in any manufacturing operation, and elevated conveyor systems are designed with built-in safety features to ensure the well-being of employees as well as the protection of materials being transported. With advanced sensors, guards, and monitoring systems, the risk of accidents and mishaps is minimized, creating a more secure and reliable material handling process.In addition to the operational benefits, elevated conveyor systems also contribute to overall cost savings for companies. By streamlining material handling processes, companies can reduce labor costs, minimize material damage, and optimize energy consumption. These systems also have lower maintenance requirements, resulting in fewer downtimes and increased productivity.As the demand for more efficient and advanced material handling solutions continues to grow, elevated conveyor systems are expected to play a pivotal role in the future of manufacturing. With their ability to improve productivity, safety, and cost-effectiveness, these systems are becoming an integral part of modern manufacturing operations.In conclusion, elevated conveyor systems have redefined material handling in the manufacturing industry, offering unparalleled efficiency, flexibility, and safety. With companies like Brand leading the way with innovative solutions, the adoption of these systems is set to grow, driving further advancements in the industry. As manufacturers continue to seek ways to enhance their operations, elevated conveyor systems will undoubtedly remain a crucial component in their quest for excellence.

Top Quality Bucket Elevator Tail Pulley for Efficient Material Handling

The innovative Bucket Elevator Tail Pulley is set to revolutionize the materials handling industry. This new product from a leading company in the industry, {Company Name}, is designed to provide maximum efficiency and reliability in conveying bulk materials vertically.The bucket elevator is a critical component in a variety of industries, including agriculture, mining, and manufacturing. It is used to transport bulk materials such as grains, fertilizers, and ores from one level to another within a facility. The tail pulley is an essential part of the bucket elevator as it provides the necessary tension to the conveyor belt, allowing for smooth and efficient material movement.{Company Name} has a long-standing reputation for delivering high-quality products that meet the demands of the most challenging materials handling applications. With the introduction of the Bucket Elevator Tail Pulley, the company is once again demonstrating its commitment to innovation and superior performance.One of the key features of the Bucket Elevator Tail Pulley is its robust construction. Made from durable materials, the tail pulley is designed to withstand the rigors of continuous operation in demanding environments. This ensures reliable performance and minimal downtime, resulting in increased productivity for the end user.In addition to its durability, the tail pulley is also designed for easy maintenance. Its innovative design allows for quick and simple access to key components, making routine inspections and servicing hassle-free. This is an important consideration for industries where downtime can result in significant financial losses.Furthermore, the Bucket Elevator Tail Pulley is engineered for optimal performance. Its precise construction and careful attention to detail result in smooth operation and minimal power consumption. This not only contributes to efficiency but also reduces operating costs for the end user.{Company Name} prides itself on its commitment to customer satisfaction. With the introduction of the Bucket Elevator Tail Pulley, the company is providing a solution that meets the evolving needs of the materials handling industry. By delivering a product that is reliable, efficient, and easy to maintain, {Company Name} is reinforcing its position as a leader in the field.In addition to the innovative design and performance of the Bucket Elevator Tail Pulley, {Company Name} also offers comprehensive support to its customers. The company's team of experts is available to provide technical assistance, troubleshooting, and training to ensure that the product is properly installed and maintained.The introduction of the Bucket Elevator Tail Pulley marks a significant milestone for {Company Name} and the materials handling industry as a whole. With its focus on innovation and customer satisfaction, {Company Name} continues to drive the industry forward, setting new standards for quality and performance.For more information about the Bucket Elevator Tail Pulley and other products from {Company Name}, please visit their website or contact their customer service team. With its dedication to excellence and a track record of success, {Company Name} is poised to continue leading the way in the materials handling industry for years to come.

Key Benefits of Implementing Uniform Feeding for Livestock

Uniform Feeding Innovates Poultry Nutrition with Advanced TechnologyWith the growing demand for high-quality poultry products, the need for efficient and effective poultry nutrition has never been greater. Uniform Feeding, a leader in the animal nutrition industry, has been at the forefront of innovation in poultry nutrition, introducing advanced technologies and products that have revolutionized the way poultry are fed and raised.Uniform Feeding, a subsidiary of a globally recognized animal nutrition company, has been a key player in the development of innovative solutions for the poultry industry. Their commitment to research and development has led to the creation of cutting-edge products and technologies that have improved the health and performance of poultry across the world.One of the company's most notable achievements is the development of a proprietary feed formulation process that incorporates the latest advances in nutrition science and technology. This process allows for precise control over the nutrient content of the feed, ensuring that poultry receive the optimal balance of proteins, vitamins, and minerals necessary for their growth and well-being. This has resulted in improved feed efficiency, reduced waste, and enhanced overall performance of the poultry.In addition to their advanced feed formulation process, Uniform Feeding has also pioneered the use of digital technologies to monitor and optimize poultry nutrition. Their innovative feed management systems allow for real-time monitoring of feed intake, allowing farmers to make adjustments as needed to ensure that their poultry are receiving the right amount of nutrients at all times. This level of precision and control has had a significant impact on the growth and health of poultry, leading to higher yields and improved product quality.Furthermore, Uniform Feeding has made a commitment to sustainability, developing products that not only improve the performance of poultry but also minimize the environmental impact of poultry production. The company has worked to reduce the use of antibiotics and other additives in their feed products, while also incorporating sustainable sourcing practices to minimize the use of natural resources. This dedication to sustainability has not only benefited the environment but has also aligned with consumer preferences for ethically and sustainably produced poultry products.The impact of Uniform Feeding's innovations has been felt across the poultry industry. Farmers who have adopted their advanced feed products and technologies have reported significant improvements in the health and performance of their poultry, ultimately leading to higher profitability and sustainability. In addition, the company's commitment to research and development has paved the way for continued advancements in poultry nutrition, ensuring that the industry remains at the cutting edge of innovation.Looking ahead, Uniform Feeding remains dedicated to driving further advancements in poultry nutrition. By leveraging the latest technologies and nutritional science, the company is poised to continue revolutionizing the way poultry are fed and raised, ultimately leading to healthier, more sustainable, and more profitable poultry production.In conclusion, Uniform Feeding has established itself as a leader in poultry nutrition, driving innovation and advancements that have reshaped the industry. With a commitment to research and development, a focus on sustainability, and a dedication to improving the performance and well-being of poultry, the company is well-positioned to continue leading the way in poultry nutrition for years to come.

The Basics of How Bucket Elevators Work

The bucket elevator is an essential piece of equipment in many industries, including agriculture, mining, and manufacturing. It is used to vertically transport bulk materials such as grain, coal, cement, and ore. The working of a bucket elevator is relatively simple yet crucial for the efficient operation of various production processes.A bucket elevator typically consists of a series of buckets attached to a chain or belt that moves in a continuous loop. The buckets are filled with the material to be transported at the bottom of the elevator and carried upwards to discharge at the top. The design of the buckets ensures that the material is effectively and smoothly transported without spillage or damage. This makes the bucket elevator an ideal solution for handling fragile or abrasive materials.The working principle of a bucket elevator is based on centrifugal discharge, continuous discharge, or positive discharge. Centrifugal discharge elevators use centrifugal force to throw the material out of the buckets at the top of the elevator. Continuous discharge elevators allow the buckets to discharge the material continuously as they pass around the head sprocket or pulley. Positive discharge elevators use a secondary discharge mechanism to ensure complete discharge of the material.Additionally, the speed and design of the bucket elevator can be customized to suit the specific requirements of the material being transported and the production process. This customization can include the size and shape of the buckets, the speed of the conveyor belt or chain, and the overall design of the elevator system.For over [Company Name]'s years, the company has been a leading manufacturer and supplier of high-quality bucket elevators for a wide range of industries. Their bucket elevators are designed to provide reliable and efficient material handling solutions, helping businesses improve their productivity and reduce operational costs. With a commitment to quality and innovation, the company has gained a reputation for delivering durable and high-performance equipment.[Company Name]'s bucket elevators are designed and manufactured to meet the specific needs of their customers. The company offers a range of customization options to ensure that their bucket elevators can effectively handle different types of materials and operating conditions. From agricultural products to industrial materials, their bucket elevators are built to withstand the demands of various applications.The company's bucket elevators are built with heavy-duty components to ensure long-term reliability and low maintenance requirements. This includes robust chains or belts, durable buckets, and sturdy support structures. Their bucket elevators are also equipped with safety features to protect both the equipment and the operators.In addition to manufacturing high-quality bucket elevators, [Company Name] also provides comprehensive installation, maintenance, and after-sales support. Their team of experienced engineers and technicians works closely with customers to ensure that the bucket elevators are installed properly and operate efficiently. The company also offers regular maintenance services to prolong the lifespan of the equipment and minimize downtime.With a dedication to customer satisfaction and a focus on continuous improvement, [Company Name] has established itself as a reliable partner for businesses in need of efficient material handling solutions. Their commitment to producing top-notch bucket elevators has earned them the trust of numerous clients across different industries.In conclusion, the bucket elevator plays a crucial role in the transportation of bulk materials in various industries. Its simple yet effective working principle, combined with customization options, ensures that it can handle a wide range of materials and operational requirements. With the expertise and quality products provided by [Company Name], businesses can rely on efficient and durable bucket elevators to streamline their production processes.

Understanding the working principle of a bucket conveyor

Bucket Conveyor Working PrincipleBucket conveyors are a popular method for transporting bulk materials in many different industries. This type of conveyor uses a series of buckets attached to a chain or belt to move materials from one location to another. The buckets scoop up the material and then are tipped to release it at the desired location. The conveyor system can be used to transport a wide range of materials, including powders, grains, pellets, and more.The principle behind bucket conveyors is relatively simple. The buckets are designed to scoop up the material as the conveyor moves along its track. Once the buckets are filled, they are carried to the discharge point where they are tipped to release the material. The empty buckets then return to the loading point to begin the cycle again.Bucket conveyors are often used in industries such as agriculture, mining, and construction. They are particularly useful for transporting materials that need to be handled with care, such as fragile grains or abrasive materials. The precise control offered by bucket conveyors makes them an ideal choice for many applications.One company that specializes in the design and manufacturing of bucket conveyors is {}. With years of experience in the industry, {} has become a leading provider of bulk material handling solutions. The company offers a range of bucket conveyor systems that are designed to meet the specific needs of their customers.{}'s bucket conveyors are built to high standards of quality and reliability. The company uses state-of-the-art technology and innovative design principles to create conveyor systems that are efficient, durable, and easy to maintain. Their conveyors are also customizable, allowing customers to tailor the system to their unique requirements.In addition to bucket conveyors, {} offers a wide range of other material handling equipment. This includes belt conveyors, screw conveyors, and drag chain conveyors, among others. The company's comprehensive range of products and services makes them a one-stop shop for all bulk material handling needs.With a focus on customer satisfaction and continuous improvement, {} has built a reputation for delivering exceptional products and service. The company works closely with its customers to understand their needs and provide solutions that exceed expectations. Whether it's a small-scale agricultural operation or a large industrial facility, {} has the expertise and resources to deliver reliable and cost-effective material handling solutions.In conclusion, the working principle of bucket conveyors is based on the simple yet effective concept of scooping, transporting, and discharging materials. When combined with {}'s expertise and dedication to quality, bucket conveyors offer a versatile and efficient solution for many material handling needs. As the demand for bulk material handling continues to grow, companies like {} will play an important role in providing the equipment and support necessary for businesses to thrive.

Ultimate Guide to Chain Type Bucket Elevators: Everything You Need to Know

Chain Type Bucket Elevator Revolutionizes Material Handling in {Company Name}Material handling is a crucial aspect of any industrial process, and the efficiency and reliability of the equipment used can have a significant impact on the overall productivity of the operation. With this in mind, {Company Name}, a leading provider of material handling solutions, has recently introduced a revolutionary new product to its extensive lineup - the {Company Name} Chain Type Bucket Elevator.The Chain Type Bucket Elevator is a game-changing piece of equipment that has already begun to make waves in the industry. It offers a host of features and benefits that set it apart from traditional bucket elevators, and it is quickly gaining recognition as a must-have for any industrial operation looking to optimize its material handling processes.One of the key features of the {Company Name} Chain Type Bucket Elevator is its robust construction. It is built to withstand the rigors of continuous heavy-duty use, and its durable design ensures that it can reliably handle a wide range of materials, from fine powders to large aggregates. This level of versatility makes it suitable for a variety of industries, including mining, agriculture, and construction.In addition to its robust construction, the Chain Type Bucket Elevator also boasts a highly efficient design. Its innovative chain and bucket mechanism allows for smooth and gentle handling of materials, minimizing the risk of damage or degradation. This is particularly important for industries handling fragile or valuable materials, as it helps to preserve the integrity of the products being transported.Furthermore, the {Company Name} Chain Type Bucket Elevator has been engineered with user-friendliness in mind. It is equipped with advanced control systems that allow for seamless operation and monitoring, and its low maintenance requirements make it a cost-effective solution for industrial operations. This combination of high performance and ease of use makes it an attractive option for businesses looking to streamline their material handling processes.{Company Name} has a long-standing reputation for delivering high-quality material handling solutions, and the introduction of the Chain Type Bucket Elevator only serves to strengthen this reputation. The company has been at the forefront of innovation in the industry for over a decade, and its commitment to continuous improvement is reflected in the development of this cutting-edge product.With a team of experienced engineers and technicians, {Company Name} has the expertise and resources to provide comprehensive support to its customers. From initial consultation and design to installation and ongoing maintenance, the company offers a complete range of services to ensure that its customers get the most out of their investment in the Chain Type Bucket Elevator.As a result, {Company Name} has already seen a strong demand for the Chain Type Bucket Elevator, with a growing number of industrial operations recognizing its potential to enhance their material handling processes. The positive feedback from early adopters of the product has further fueled the company's confidence in the market potential of this innovative solution.In conclusion, the introduction of the {Company Name} Chain Type Bucket Elevator is a significant milestone for {Company Name} and a major development for the material handling industry as a whole. Its robust construction, efficient design, and user-friendly features make it a highly desirable solution for a wide range of industrial applications, and it is poised to revolutionize material handling processes for years to come. With its track record of excellence and commitment to customer satisfaction, {Company Name} is well-positioned to lead the way in this exciting new era of material handling technology.

Durable and Reliable Material for Conveyors: A Guide to Belt Options

The demand for belt material for conveyors is on the rise as industries continue to grow and develop. Belt conveyors are essential equipment used in various industries such as manufacturing, logistics, mining, agriculture, and food processing. They are designed to transport heavy and bulky materials efficiently and safely, making the production process more seamless and productive.One of the key players in the belt material for conveyor industry is {}. With decades of experience in the manufacturing and supply of conveyor belts, they have established themselves as a reliable and trusted partner for many companies seeking high-quality conveyor solutions. Their dedication to innovation and excellence has allowed them to develop a diverse range of conveyor belt materials that cater to the specific needs and challenges of different industries.The company's extensive range of belt materials for conveyors includes rubber, PVC, and PU belts, each designed to offer unique advantages and performance capabilities. Rubber belts are known for their durability and resistance to abrasion, making them suitable for heavy-duty applications in mining and construction. PVC belts are lightweight and flexible, ideal for food processing and packaging applications. PU belts offer excellent resistance to oils and chemicals, making them a popular choice for the automotive and manufacturing industries.In addition to offering a wide range of belt materials, {} also provides customized solutions to meet the specific requirements of their customers. Their team of engineers and experts work closely with clients to understand their needs and develop tailor-made conveyor belt solutions that optimize efficiency and performance.In recent years, the company has also invested in research and development to introduce innovative materials and technologies to improve the performance and lifespan of conveyor belts. By leveraging the latest advancements in materials science and manufacturing processes, they have been able to introduce conveyor belt solutions that offer higher tensile strength, reduced elongation, and better resistance to wear and tear.Furthermore, {}. has also recognized the importance of sustainable and eco-friendly practices in the industry. As a result, they have integrated environmentally friendly materials and processes into their manufacturing operations, ensuring that their products are in line with global sustainability standards. This commitment to sustainability not only benefits the environment but also helps their customers meet their own sustainability targets.With a strong focus on quality and reliability, {} has built a solid reputation in the industry, earning the trust and loyalty of their customers. Their conveyor belt materials are known for their high performance, longevity, and cost-effectiveness, making them the preferred choice for many companies across different sectors.As the demand for conveyor belt materials continues to grow, {} is poised to expand its presence in the market, offering innovative solutions that cater to the evolving needs of industries. With a strong commitment to excellence and customer satisfaction, they are well-positioned to remain a leader in the conveyor belt material industry for years to come.

Urea Chemical Fertilizer: Benefits and Uses in Agriculture

Urea Chemical Fertilizer, a leading company in the agricultural and chemical industry, is revolutionizing the way farmers fertilize their crops. With a focus on innovation and sustainability, the company is dedicated to providing high-quality fertilizers that not only enhance crop yields but also minimize environmental impact.Established in 1980, Urea Chemical Fertilizer has been at the forefront of delivering cutting-edge agricultural solutions to farmers worldwide. The company's state-of-the-art production facilities and research laboratories are equipped with the latest technology, allowing for the development of superior fertilizers that meet the evolving needs of modern agriculture.One of the company's flagship products is a high-purity urea-based fertilizer that is specifically designed to maximize crop productivity while minimizing the release of greenhouse gases. Urea Chemical Fertilizer has invested significantly in research and development to formulate this fertilizer, which is known for its high nitrogen content and efficient nutrient release. As a result, farmers can achieve higher yields while using fewer resources, thus reducing their environmental footprint.Moreover, Urea Chemical Fertilizer is committed to promoting sustainable agricultural practices. The company provides comprehensive support and training to farmers on the proper and efficient use of its fertilizers, ensuring that they are applied in a manner that minimizes waste and environmental impact. By partnering with agricultural experts and institutions, the company also conducts extensive research to optimize its fertilizers for various crops and growing conditions.In addition to its focus on sustainability, Urea Chemical Fertilizer is dedicated to ensuring the quality and safety of its products. The company adheres to strict quality control measures throughout the production process, from sourcing raw materials to the final packaging of fertilizers. Furthermore, Urea Chemical Fertilizer continually invests in modernizing its manufacturing facilities to uphold the highest standards of product quality and safety.The company's unwavering commitment to excellence has earned it a stellar reputation in the agricultural industry. Urea Chemical Fertilizer has built strong, long-lasting relationships with farmers, distributors, and industry partners, and has become a trusted supplier of fertilizers worldwide.Urea Chemical Fertilizer's impact goes beyond its products and services. The company is actively involved in corporate social responsibility initiatives, aiming to benefit the communities in which it operates. From sponsoring educational programs for young farmers to supporting environmental conservation projects, Urea Chemical Fertilizer is dedicated to making a positive impact in society.Looking to the future, Urea Chemical Fertilizer is poised to continue its legacy of excellence and innovation. The company is constantly exploring new avenues for sustainable agriculture, including the development of advanced fertilizers that cater to the evolving needs of farmers and the environment. With a team of dedicated professionals and a steadfast commitment to success, Urea Chemical Fertilizer is well-positioned to lead the way in shaping the future of global agriculture.In conclusion, Urea Chemical Fertilizer is a leading force in the agricultural industry, driven by a passion for innovation, sustainability, and excellence. With its high-quality fertilizers, unwavering commitment to sustainability, and dedication to making a positive impact, the company is a true catalyst for change in the world of agriculture. Urea Chemical Fertilizer continues to set the bar high for itself and the industry, ensuring that farmers have access to the best tools and solutions to cultivate a sustainable and productive future.

High-quality Industrial Bucket Elevator for Efficient Material Handling

Industrial Bucket Elevator Revolutionizing Material Handling in ManufacturingIn the world of manufacturing and material handling, efficiency and productivity are top priorities for companies looking to succeed in a competitive industry. This is where Industrial Bucket Elevators play a crucial role, providing a solution for moving materials vertically in a safe and efficient manner. With advancements in technology and design, the Industrial Bucket Elevator has revolutionized material handling processes in manufacturing facilities around the world.{Company name} is a leading manufacturer of Industrial Bucket Elevators, specializing in providing high-quality, innovative solutions for a wide range of industries. With a strong focus on research and development, {Company name} has been at the forefront of revolutionizing material handling processes through their state-of-the-art Industrial Bucket Elevators.The Industrial Bucket Elevator is a versatile piece of equipment that is designed to handle a variety of materials, including grains, fertilizers, aggregates, and more. Whether it's bulk materials in a cement plant, or processed foods in a production facility, the Industrial Bucket Elevator provides a reliable and efficient method for vertical transportation of materials.One of the key advantages of the Industrial Bucket Elevator is its ability to handle materials with various characteristics, such as size, density, and moisture content. The design of the bucket elevator allows for gentle handling of materials, minimizing the risk of damage or degradation during transportation. This is particularly important for industries that handle delicate or fragile materials, where maintaining the integrity of the product is essential.Additionally, the Industrial Bucket Elevator is designed with safety in mind, incorporating features such as interlocking doors, emergency stops, and safety guards to ensure the protection of workers and the prevention of accidents. This makes it a reliable and secure solution for material handling in manufacturing environments.Furthermore, {Company name} offers customizable solutions to meet the specific needs of their customers. From the design and construction of the elevator to the selection of materials and components, {Company name} works closely with their clients to ensure that the Industrial Bucket Elevator is tailored to their unique requirements. This customization allows for seamless integration of the elevator into existing manufacturing processes, optimizing efficiency and productivity.With a commitment to quality and reliability, {Company name} has earned a reputation for delivering Industrial Bucket Elevators that are durable, low-maintenance, and cost-effective. This has made them a preferred choice for companies seeking a long-term solution for their material handling needs.The Industrial Bucket Elevator has seen a surge in demand as industries continue to prioritize efficiency, safety, and sustainability in their manufacturing processes. {Company name}'s dedication to innovation and excellence positions them as a leader in providing cutting-edge solutions for material handling needs across various industries.Looking ahead, {Company name} is focused on further advancing the capabilities of the Industrial Bucket Elevator, with a continued emphasis on technological innovation and sustainability. By staying ahead of industry trends and customer demands, {Company name} remains committed to revolutionizing material handling in manufacturing through their state-of-the-art Industrial Bucket Elevators.In conclusion, the Industrial Bucket Elevator has played a significant role in transforming material handling processes in manufacturing, providing a reliable, efficient, and customizable solution for vertical transportation of materials. With {Company name}'s dedication to quality and innovation, the future looks promising for the continued evolution of the Industrial Bucket Elevator and its impact on the manufacturing industry.